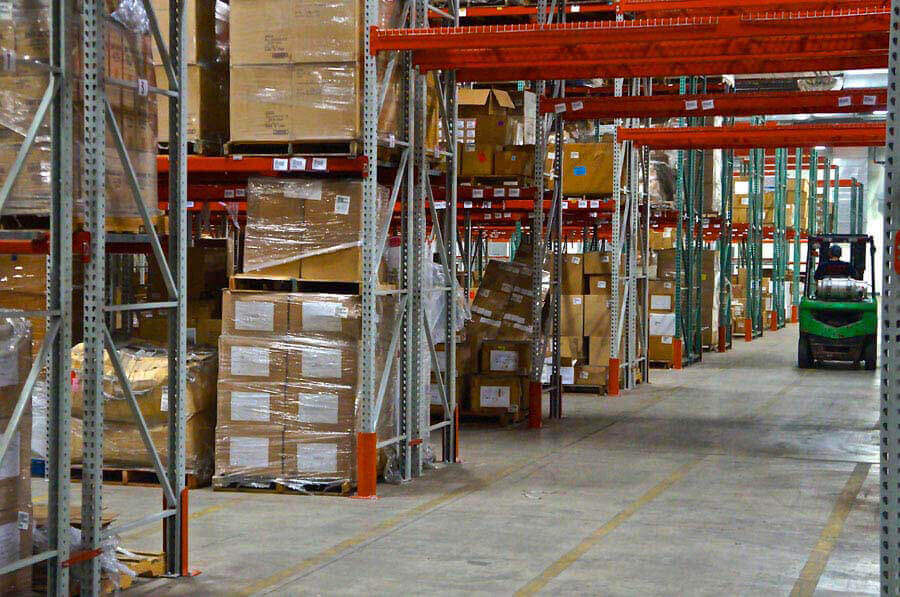

Frequently Asked Questions about Structural Warehouse Pallet Storage

Roll-form pallet shelving is usually associated with selective pallet rack shelving & record storage. It is the preferred warehouse shelving for light (500 lbs. per shelf) to heavy (7,500 lbs. per shelf) pallet storage.

Structural pallet shelving is made from hot rolled c-channel structural steel. While it can be used to store lighter loads, it's structural design can also be best utilized when storing heavier loads of 5,000 lbs. per shelf and more. It uses additional hardware (nuts and bolts) for assembly. It is inherently heavier, stronger and can hold heavier loads than roll-form rack. It is more impact resistant than roll-form rack.

While roll-form rack is the rack of choice for selective pallet storage, structural rack is often the preferred solution for higher density applications like pushback, drive in and pallet flow applications. Structural racks are thicker and the heavier construction offers improved resistance to impact from forklifts entering and exiting the racks.

Structural racks typically cost more per pallet position to buy, ship and install than roll-form racks. Structural racks may offer more rust resistance and hold capacity than roll-form racks.

You would consider using heavy duty roll-form warehouse racks:

- When you are storing light to heavy weight loads, usually 7,500 lbs. or less per shelf.

- When transportation costs are a concern. Because of its lighter weight, more roll form rack can be put on a flat bed when transporting racks to the job site for installation.

- When easy handling and quick assembly without the need for hardware is desired.

Due to its heavier weight, structural warehouse rack costs more to ship than roll-form. Roll-form rack is less costly to ship because it's lighter than structural racks with the same dimensions.

Due to its heavier weight and nut and bolt connections, structural warehouse racking can take longer and cost more to handle and install. Tools are required to attach and tighten the nuts & bolts used to connect the shelf beams to the upright frames. Roll form racks traditionally install faster due to its bolt-less connection design, which allows for a fast and easy connection of the beams to the uprights.

You would consider using structural pallet or cantilever racking instead of roll-form racking:

- Due to its impact resistance and ability to hold heavier weight, structural racks are often the preferred pallet storage system choice of warehouse managers for push back, drive in and drive through racks.

- When bigger capacities are needed for heavier loads.

- When items need to be washed down. Structural rack is easier to get access to all surface areas.

- When storing heavy items like tool & die equipment and steel coils.

Due to its ability to hold heavier weights and nut and bolt connections, structural racks are the preferred choice for most warehouse managers for pushback racking, drive through and drive in racks. Roll-form racks traditionally install faster due to its bolt-less connection design, however roll-form racks are more susceptible to forklift impact damage.

When selecting pallet rack storage systems, it is best to understand the full range of pallet storage systems available, while paying attention to each of the features and benefits. Call or email one of our solutions specialists for help - they are familiar with all the different solutions available and will be happy to review your project and provide you the most efficient and cost-effective solutions available.